news

why has permanent magnet synchronous motor become the main driving motor?

2023-04-18 15:59:10来源:

with the popularization of new energy vehicles, the drive motor has become one of the core components of new energy vehicles. among them, permanent magnet synchronous motor, as a high-efficiency and high output torque motor, has become one of the most widely used driving motors for new energy vehicles.

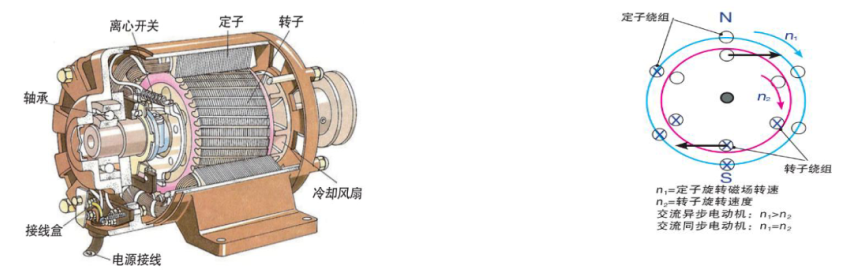

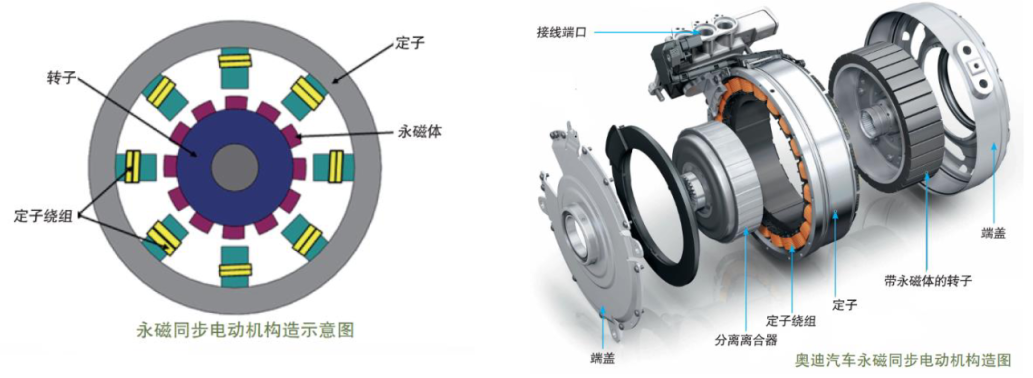

the working principle of permanent magnet synchronous motor is to use the rotating magnetic field generated by energizing the stator winding to drive the permanent magnet of the rotor to rotate. during operation, the rotational speed of the rotor is synchronized with the rotational speed of the magnetic field, hence it is called a "synchronous motor". in contrast, the working principle of ac asynchronous motor is to generate rotating magnetic field by energizing the stator winding, which causes the induced current of the rotor and then drives the rotor to rotate. because the rotational speed of the rotor is not synchronized with the rotational speed of the magnetic field, it is called an "asynchronous motor".

in the field of new energy vehicles, permanent magnet synchronous motors have become one of the most widely used driving motors for new energy vehicles due to their obvious advantages in power to mass ratio, volume, mass, output torque, limit speed, and braking performance.

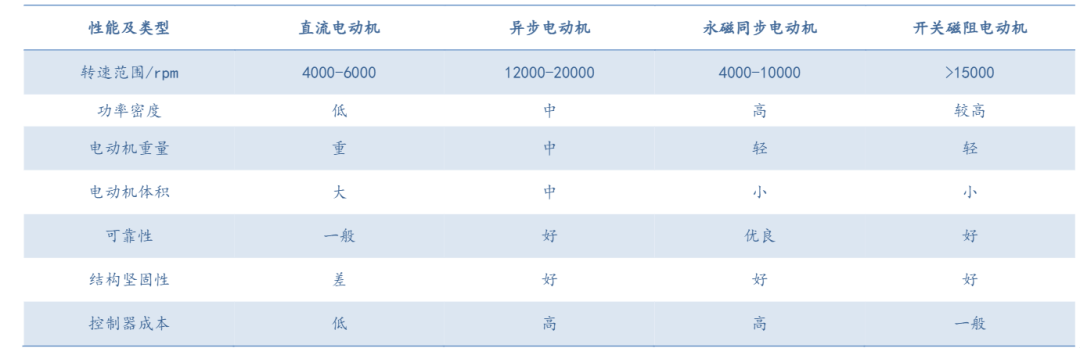

classification of commonly used motors suitable for electric drive

firstly, permanent magnet synchronous motors have a high power to mass ratio. due to the use of permanent magnets as the rotor in permanent magnet synchronous motors, higher output power and higher power density can be achieved at the same speed. this makes permanent magnet synchronous motors have significant advantages in both volume and weight, making them suitable for use in fields such as new energy vehicles that have strict requirements for volume, weight, and energy density.

secondly, the output torque of permanent magnet synchronous motors is greater. the rotor of a permanent magnet synchronous motor is composed of permanent magnets, which can generate a strong magnetic field during rotation, providing greater output torque. this enables permanent magnet synchronous motors to have better power output capabilities in acceleration and hill climbing scenarios, making them suitable for vehicles that require high power output.

upper left: schematic diagram of single-phase asynchronous motor structure

upper right: schematic diagram of asynchronous motor working principle

thirdly, permanent magnet synchronous motors have high limit speed and braking performance. due to the use of permanent magnets as the rotor in permanent magnet synchronous motors, their rotor weight is relatively light, their moment of inertia is small, and they can reach higher limit speeds. at the same time, the braking performance of permanent magnet synchronous motors is also relatively excellent, which can quickly stop and improve the safety performance of the car.

fourthly, permanent magnet synchronous motors have high efficiency. due to the fact that permanent magnet synchronous motors do not require energy absorption excitation, their efficiency is higher than that of ac asynchronous motors. in new energy vehicles, high efficiency is an important means to achieve energy conservation and reduce energy consumption. therefore, permanent magnet synchronous motors have become one of the most widely used driving motors in new energy vehicles due to their high efficiency.

in addition to the above advantages, permanent magnet synchronous motors also have an important advantage, which is their good speed regulation performance. when facing complex driving scenarios such as repeated start stop, acceleration and deceleration, permanent magnet synchronous motors can maintain high efficiency, thereby improving the energy utilization and driving range of the car.

upper left: schematic diagram of permanent magnet synchronous motor structure

above right: structure diagram of audi permanent magnet synchronous motor

of course, permanent magnet synchronous motors also have some drawbacks. for example, when permanent magnet materials are subjected to vibration, high temperature, and overload current, their magnetic conductivity may decrease, or demagnetization may occur, which may reduce the performance of permanent magnet motors. at the same time, rare earth materials are essential raw materials for manufacturing permanent magnet synchronous motors, and their prices are relatively unstable, which also increases the cost of permanent magnet synchronous motors.

permanent magnet synchronous motor (pmsm) has become one of the most widely used driving motors in new energy vehicles due to its advantages in power to mass ratio, volume, mass, output torque, extreme speed, and braking performance. of course, different car manufacturers choose different drive motors based on different design and performance requirements, so there will also be a certain proportion of new energy vehicles driven by ac asynchronous motors in the market. however, with the continuous development and upgrading of technology, it is believed that the application prospects of permanent magnet synchronous motors in new energy vehicles are still very broad, and there will be more new technologies and innovative applications in the future.