news

which is more efficient, ac induction motor or permanent magnet synchronous motor?

2023-04-13 09:24:10来源:

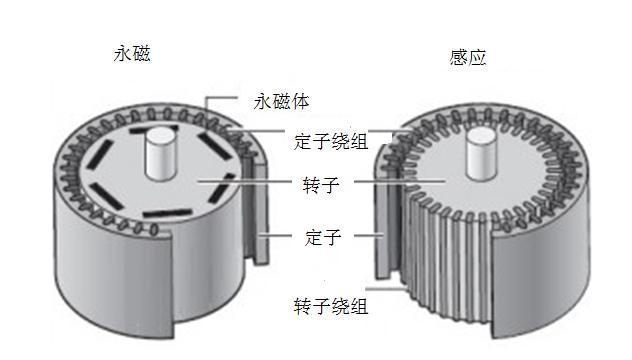

in industrial and commercial applications, most pumps and fans are driven by ac induction motors. "ac induction motors" are asynchronous motors that rely on current to rotate the rotor. torque is generated by the current in the rotor, and current is generated by the magnetic field of the stator winding through electromagnetic induction. the rotor always rotates at a speed lower than the magnetic field. "permanent magnet synchronous motor" relies on magnet to rotate the rotor, and the speed of the rotor is the same as that of the internal rotating magnetic field of the permanent magnet synchronous motor.

permanent magnet motors must use drivers

ac induction motors can drive pumps or fans without variable frequency drives, which are usually installed in the pump or fan system to improve system efficiency. a permanent magnet synchronous motor requires a driver to operate and cannot operate without a driver. in order to accurately control the speed of permanent magnet synchronous motors to meet application requirements such as pressure, flow rate, volume, etc., a frequency converter is required. some new frequency converters have been equipped with permanent magnet motor control options as standard functions, allowing operators to control permanent magnet motors to drive fans and/or pumps, resulting in higher efficiency.

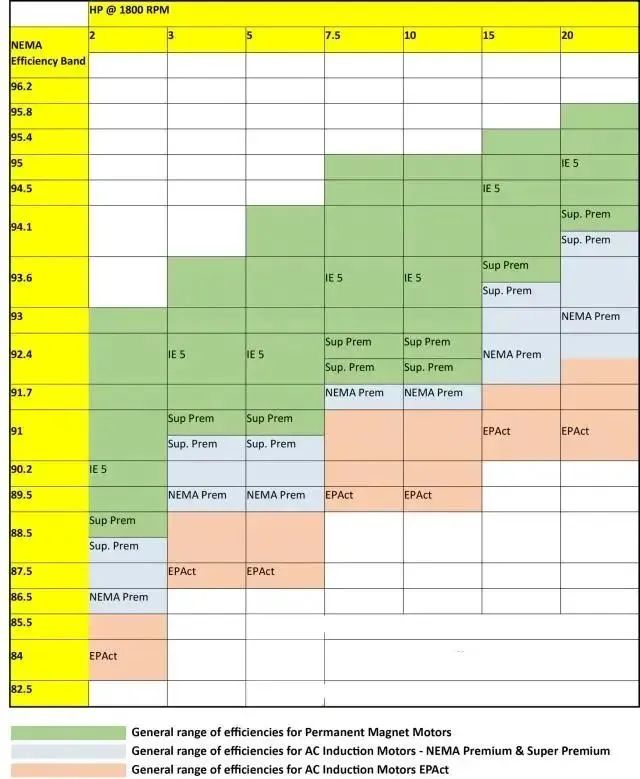

compared with ac induction motors, permanent magnet motors can significantly improve efficiency. the full load efficiency of permanent magnet motors is higher than that of ac induction motors. the efficiency range between ac induction motors and permanent magnet motors is shown below.

variable frequency drives do not improve motor efficiency, and they help improve system efficiency within the operating speed range, as most systems do not always operate at the highest speed. variable frequency drives help improve system efficiency because they have the ability to reduce the speed of motors, fans, or pumps, rather than turning valves to throttle the pump or closing dampers to prevent air flow.

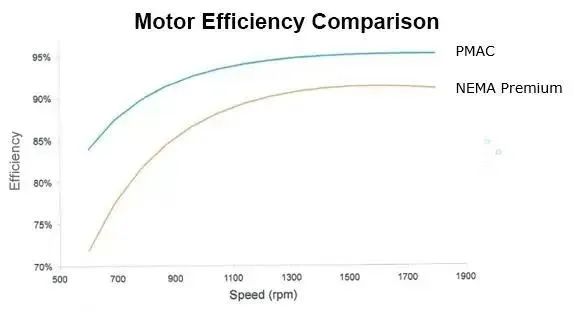

the above figure compares the 10 horsepower 1800 rpm permanent magnet synchronous motor pmac with the advanced ac induction motor nema, which operates with variable torque load in the speed range of 100 to 500. in both cases, the efficiency of both motors will decrease. at 600 rpm, the efficiency of nema high-quality motors decreased from about 90% to about 72%, and pmac decreased from about 94% to 83%. when the operating system affects equipment efficiency, permanent magnet motors have been proven to have higher efficiency than ac induction motors.

advantages and disadvantages of permanent magnet motors

although ac induction motors are more common in motor drive systems, they are usually larger in size and lower in efficiency than permanent magnet motor solutions. although permanent magnet motor solutions often have higher initial costs, they can provide smaller dimensions and, more importantly, higher efficiency for more compact mechanical packaging. permanent magnet motors are often more expensive and difficult to start than ac induction motors. however, the advantages of permanent magnet motors include higher efficiency, smaller size (permanent magnet motors can reach one-third of the size of most ac motors, making installation and maintenance much easier), and the ability to maintain full torque at low speeds.

the trend is changing

the combination of permanent magnet motors and variable frequency drives is not entirely new. design engineers and equipment owners are starting to choose more permanent magnet motor solutions for fan and pump applications, as they are smaller and more efficient. variable frequency drives require a special algorithm to drive permanent magnet motors. now, there are some new variable frequency drives on the market that have a built-in standard feature to control permanent magnet motors without requiring additional costs. as more and more manufacturers of variable frequency drives begin to add high-performance control functions to permanent magnet motors, users will tend to install motor systems with higher operating efficiency, smaller packaging, and lower costs.