news

what are the characteristics and advantages and disadvantages of permanent magnet synchronous motors?

2023-04-23 16:24:50来源:

一、characteristics of permanent magnet synchronous motors

1. voltage regulation

the automatic regulation excitation system can be seen as a negative feedback control system with voltage as the regulated variable. the reactive load current is the main reason for the drop of generator terminal voltage. when the excitation current is constant, the generator terminal voltage will decrease with the increase of reactive current. however, in order to meet the user's requirements for power quality, the terminal voltage of the generator should remain basically unchanged. the way to achieve this requirement is to adjust the excitation current of the generator with the change of reactive current.

2. adjustment of reactive power

when the generator operates in parallel with the system, it can be regarded as the bus operation with infinite capacity power supply. to change the excitation current of the generator, the induced electromotive force and stator current will also change, and then the reactive current of the generator will also change. when the generator operates in parallel with an infinite capacity system, in order to change the reactive power of the generator, it is necessary to adjust the excitation current of the generator. at this point, the changed excitation current of the generator is not commonly referred to as "voltage regulation", but simply changes the reactive power fed into the system.

3. distribution of reactive load

the generators in parallel operation shall distribute reactive current in proportion according to their respective rated capacity. large capacity generators should bear more reactive loads, while smaller capacity generators should provide less reactive loads. in order to achieve automatic distribution of reactive loads, the excitation device with automatic high-voltage regulation can be used to change the excitation current of the generator to maintain its terminal voltage unchanged. the inclination of the voltage regulation characteristics of the generator can also be adjusted to achieve reasonable distribution of reactive loads of parallel running generators.

二、the permanent magnet motor drive system has the following advantages:

1. simple and compact structure

permanent magnet synchronous motors use permanent magnets to generate air gap magnetic fields, unlike commutator motors that use excitation coils to generate air gap magnetic fields, or induction motors that use the excitation component of stator current to generate air gap magnetic fields. moreover, they have simple structures, low losses, and high efficiency. permanent magnet synchronous motors can be divided into two types: surface mounted permanent magnet synchronous motors (spms) and embedded permanent magnet synchronous motors (ipms). the domestically developed permanent magnet synchronous motor is an embedded permanent magnet synchronous motor (ipm) with permanent magnets embedded inside the rotor core. for ipm motors, the permanent magnet is embedded inside the rotor, and the iron core provides good protection against centrifugal force, corrosion, and other possible damage to the permanent magnet during production. ipm motors have strong magnetic field saliency, and through control, the reluctance torque can be fully utilized to achieve higher torque output. at the same time, due to the saliency effect, the weak magnetic control range of the motor is greatly increased, thereby greatly increasing the speed range of the motor.

2. high efficiency, high power factor

permanent magnet synchronous motor combines the advantages of traditional asynchronous motor and electric excitation synchronous motor, and can achieve similar or even better speed regulation characteristics than dc motor, comprehensively improving its performance. compared with asynchronous motors, permanent magnet synchronous motors do not require reactive excitation current, which can significantly improve power factor, reduce stator current and stator copper loss. moreover, there is no rotor copper loss during stable operation. due to the reduction of total loss, the capacity of the motor cooling system is reduced, thereby reducing the corresponding additional loss. therefore, its efficiency is improved by 2-15 percentage points compared to asynchronous motors of the same specification.

3. strong dynamic response and overload capability

synchronous motors have stronger tolerance to torque disturbances and can respond quickly compared to asynchronous motors. when the load torque of an asynchronous motor changes, it is required that the slip rate of the motor also changes accordingly, that is, the speed of the motor changes accordingly, but the inertia of the rotating part of the system hinders the fast response of the motor. when the load torque of a synchronous motor changes, as long as the power angle of the motor is appropriately changed and the speed remains unchanged at the original synchronous speed, the inertia of the rotating part will not affect the fast response of the motor to the torque. the maximum torque of a permanent magnet synchronous motor can reach more than three times the rated torque, which is very beneficial for the stable operation of the motor system under conditions with significant changes in load torque.

4. small size and light weight

in recent years, with the continuous application of high-performance permanent magnet materials, the power density of permanent magnet synchronous motors has greatly improved. compared with asynchronous motors of the same speed and capacity, there is a significant reduction in volume and weight, which makes them widely used in many special occasions.

5. high reliability and low operation and maintenance costs

compared with dc motors and electric excitation synchronous motors, permanent magnet synchronous motors have no brushes, simplifying their structure and increasing reliability. the direct drive system eliminates the gearbox, reduces fault points, and improves system reliability. at the same time, it also reduces operating and maintenance costs.

三、however, permanent magnet synchronous motors also have the following drawbacks:

the cost of motors is relatively high; in constant power mode, the operation is more complex and the control system cost is higher; poor weak magnetic ability and limited speed range; the power range is relatively small, and due to the influence and limitation of magnetic material technology, the maximum power is only a few tens of kilowatts; at low speeds, the rated current is high, the loss is high, and the efficiency is low; when permanent magnet materials are subjected to vibration, high temperature, and overload current, their magnetic conductivity may decrease or demagnetize, which will reduce the performance of permanent magnet motors and even damage them in severe cases. strict control must be exercised during use to prevent overload. the magnetic field of permanent magnet materials is not variable, and to increase the power of the motor, its volume will be large; poor corrosion resistance; not easy to assemble.

四、extension: comparison of various motors

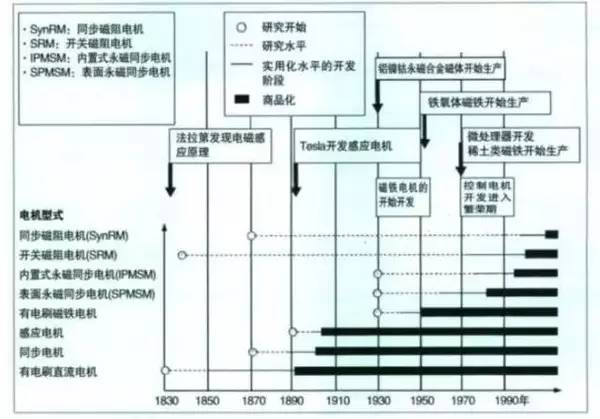

let's first compare the development history of various motors. from the figure below, we can see that brush dc motors, general synchronous motors, induction motors, and brush magnet motors have the longest commercialization history, and their products are constantly updated and still in use. since the 1980s, surface permanent magnet synchronous motors, as well as switched reluctance motors, built-in permanent magnet synchronous motors, and the latest synchronous reluctance motors developed since the 1990s, have entered the market and have been applied in electric vehicles and hybrid vehicles.

comparison of the development history of various electric motors

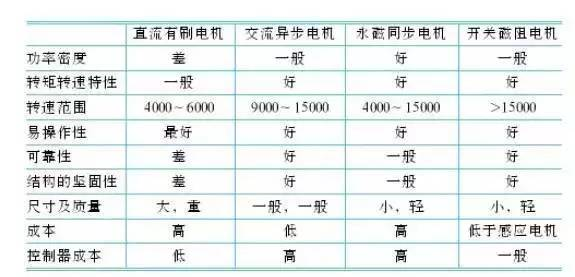

at present, the basic performance comparison of various drive motors is as follows:

comparison of basic performance of various drive motors

then compare which new energy vehicles have a wide range of applications for various motors. asynchronous motors are mainly used in pure electric vehicles, permanent magnet synchronous motors are mainly used in hybrid electric vehicles, and switched reluctance motors are currently mainly used in passenger cars. from the application of different types of new energy vehicle drive motors in china, currently, ac asynchronous induction motors and switched reluctance motors are mainly used in new energy commercial vehicles, especially in new energy buses. the actual assembly application of switched reluctance motors is relatively small; permanent magnet synchronous motors are mainly used in new energy passenger vehicles.